Community Blogs

13 total BlogsBuilders's Logs

Post and track any aviation related topic you can dream of; Builder's Log, Upgrade Log, Rebuild or Maintenance Log, and more!

—Create unlimited posts with photos, videos, and other documents

—Track time and expenses (which can be public or private)

—Share your Builder's Log on other social media platforms, and other Hangar Flying Community Members can follow and comment – or you can keep it private

—You can even back-date your posts if you wish to move your project, or other aviation blog, from another platform!

Click on New Builder's Log below to get started today…

Search Blogs

Hangar Flying e-News Images

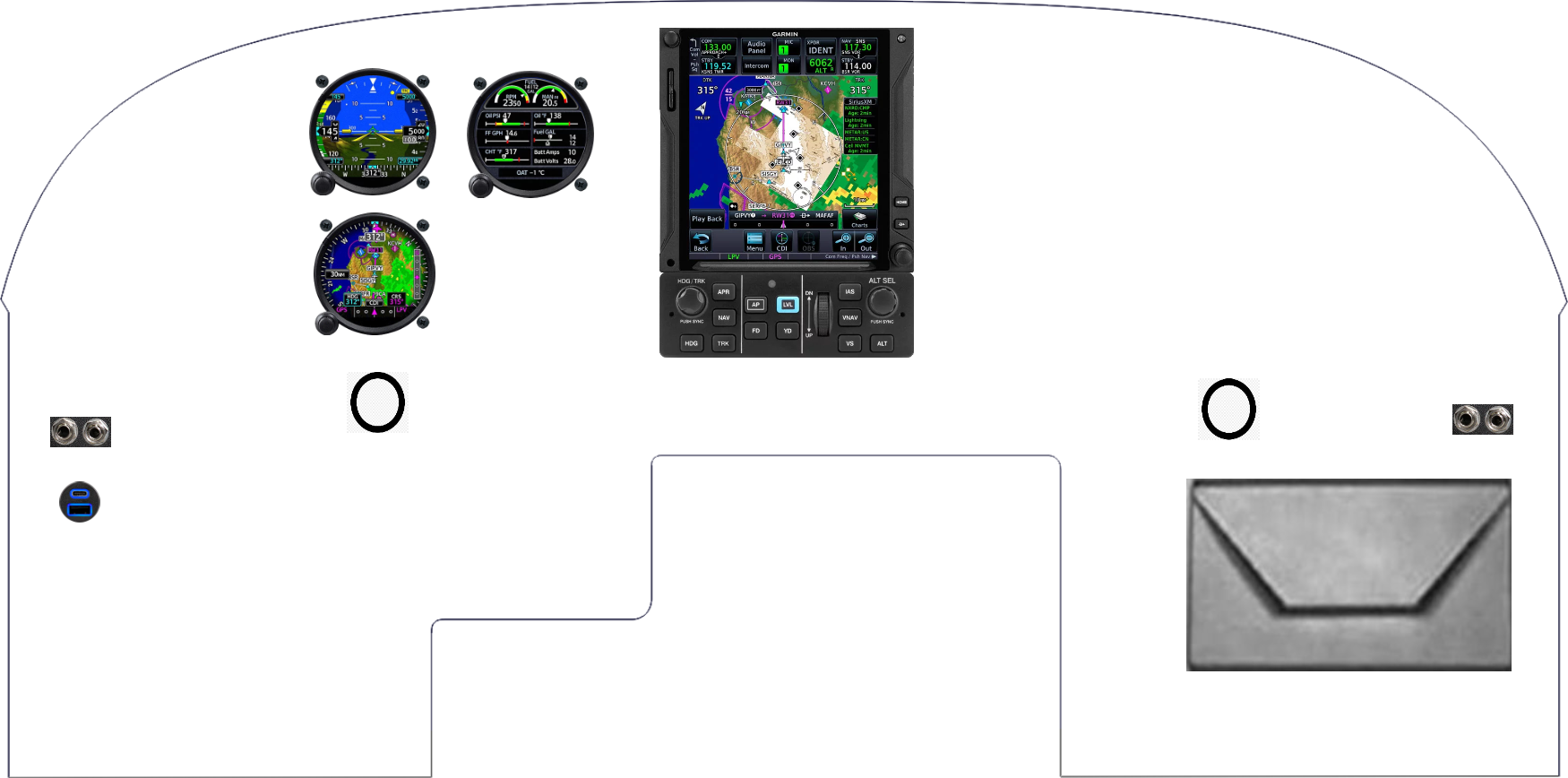

Kitfox 4 panel

design

Building the CX4

Will document the construction of a new Just SuperSTOL XL

90% Complete, 90% left to do. Prior builders choose good upgrades/changes over the years, such as dual hydraulic brakes Good to excellent detail work. As the latest builder (goal is to complete in 2 years). Edit (08/29/2023) - Bwaahahaha! Many things need to be checked out, validated during the start of the process. Engine was assembled in 2010 and never run. I've got the turbo upgrade kit to put on and will do a partial teardown/overhaul at the same time. The first 1.5 years of my ownership is getting the garage ready for this unexpected purchase. Some riveting left to do, partial glass panel to complete/test. Decide how to implement ADS-B out, and if is feasible without fully investing in new glass.

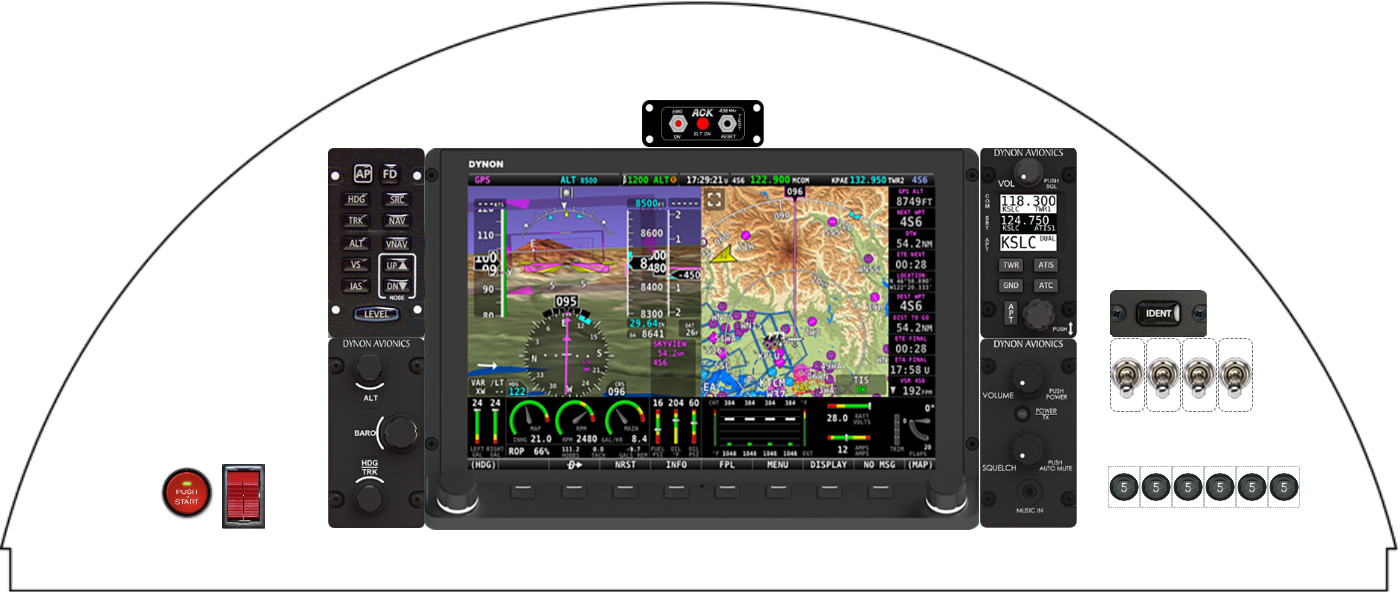

Check these panels that were designed and completed by our users!

Just some photos and videos from the Kelly Airpark 2022 Pancake Breakfast!

http://kellyairpark.org/

Panel upgrade

Mooney M20E classic design

- Hangar Flying's SS750z Builder's Log

- This project and this Builder's Log is a work in progress

- Aircraft – Zenith STOL CH750

- Engine – Rotax 912 ULS Zipper big bore – 116 HPProp – TBD but leaning toward a 2 or 3-blade ePropPanel – 12.9" iPad Pro, Levil 3 AW, GRT EIS and TQ radios

I found this factory quick build kit that was partially built and decided maybe it was a good time to build another airplane…even though I travel 7-8 months a year for work. What was I thinking! ? Anyway, you are welcome to follow along, comment, ask questions, and hopefully, it will help some other builders along the way. I deploy for work about 6-7 months a year, so there may be some gaps in my updates. I also added all posts prior to April 2022 well after I had taken the photos...but going forward I will do a better job of posting updates!

Hi to anyone who has information about the Zipper Big Bore Kit for the 912S Rotax engine. I am interested in increasing the HP of my 912S but when I tap on the Zipper website a message pops up saying "There has been a critical error on this website". I am wondering if this means Zipper no longer sell/support this Kit for the Rotax 912S ??. Can anyone shed any light on this please ?. Thanks in advance. Regards, Allen B.

172

172

CH 750 Cruzer

CH 750 Cruzer

PA-28

PA-28

PA-28

PA-28

PA-28

PA-28

PA-28

PA-28

CH 750 Cruzer

CH 750 Cruzer

172

172

Delta

Delta

Glastar

Glastar

CH-601/601XL

CH-601/601XL

172

172

CH-601/601XL

CH-601/601XL

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-7/9

RV-4

RV-4

PA-28

PA-28

PA-28

PA-28

172

172

RV-8

RV-8

RV-8

RV-8

PA-20/22

PA-20/22

PA-20/22

PA-20/22

RV-8

RV-8

T210N

T210N

Baron 55

Baron 55

Baron 55

Baron 55

RV-8

RV-8

Cherokee 180C

Cherokee 180C

Baron 55

Baron 55

M20C M20E M20F

M20C M20E M20F

CE23 / CE24

CE23 / CE24

182B/C

182B/C

Baron 55

Baron 55

R-80 Tiger Moth

R-80 Tiger Moth

Baron 55

Baron 55

Baron 55

Baron 55